ELECTRIC VEHICLE DESIGN, ENGINEERING & PROTOTYPING

We help our clients design and manufacture electric vehicles and self-driving cars. We had over two decades of experience working with electric vehicles and have helped with many aspects of the design, construction and testing of EVs and have trusted sources in Canada, the US and China for EV components which we can draw upon.

Vehicle Examples

• Experimental Electric Vehicles

• Last Mile Delivery Vehicles

• Tricycles / Quadricycles

• Electric Cargo Bikes

• Electric Scooters & Mopeds

• Electric Hydro-Foiling Surfboards

• Electric All-Terrain Vehicles

Capabilities:

-

Vehicle Architecture Design

-

Battery Enclosure / Battery Pack Design

-

Electrical Connector Design

-

Custom Brushless Motor Design & Manufacturing

-

Aerodynamic Simulation

-

Chassis Design

-

Suspension, Steering & Braking Systems Design

PROTOTYPING & VALIDATION

Early low fidelity prototypes made from Lego and 3d prints help us see the structural and mechanical challenges the vehicle will have, before getting too far down the wrong path, we can quickly iterate and avoid major vehicle problems later- then get into designing a high fidelity model.

this is especially powerful when exploring uncharted territory with novel vehicle designs. with WALLE, a transforming vehicle - the Lego model chassis had a strong tendency to twist, rolling outwards on the sides, we could see the stresses the vehicle would face, and were able to design the spaceframe to be extremely rigged in key areas to counteract this.

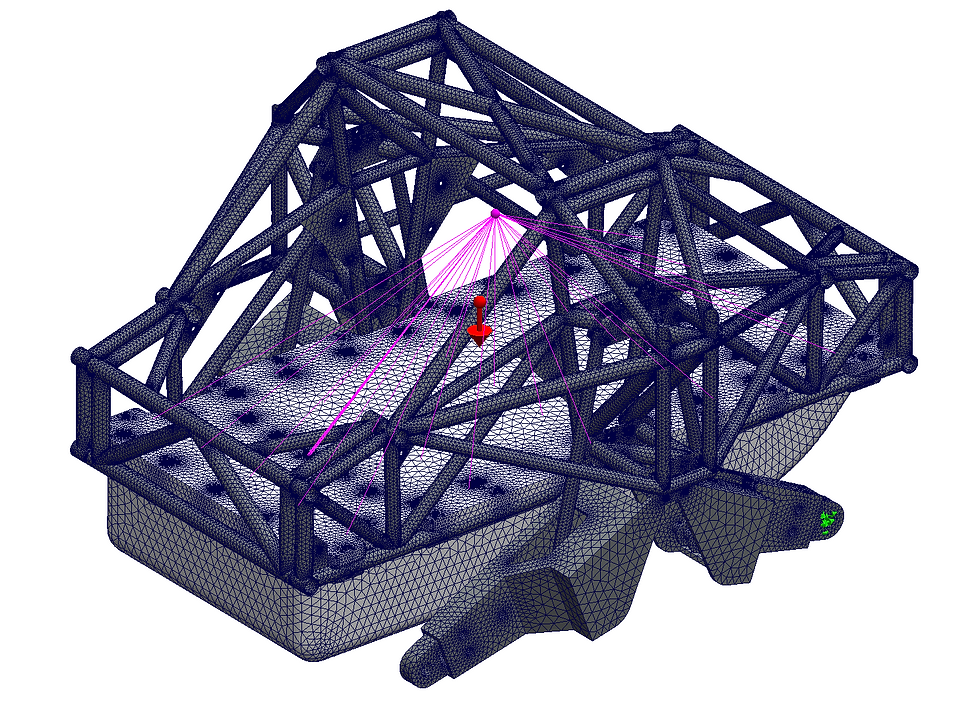

ANALYSIS / SIMULATION

learning from the low fidelity prototype- We anticipate the loads on the chassis, and set up simulations accordingly to iterate and arrive at the best design

DESIGN FOR MANUFACTURING

DFM will help you take your project from prototype to a manufacturable effective solution. We begin design for manufacturing early in our process to help our clients have a smooth launch.

During the COOKEE moped project, our client operation motors had a design they started with, and we were able to work with them to engineer it to be manufacturable without compromising the industrial design they provided us. not only that but we also worked closely with our chassis supplier VR3 to ensure effective and affordable manufacturability.

CERTIFICATION & TESTING

We are a lab, and often make custom scientific equipment to validate a wide variety of components. We build custom models for spec'ing parts like motors based on hill climb requirements, simulate, test, and analyse battery thermal cycles and thermal runaway failures. Not only do we develop and utilise the scientific equipment for these analysis, we will also train your team to run the equipment and analysis tools so you can run it independently in the future.

START YOUR PROJECT:

We are eager to help you develop your vehicle